When planning any build, the type of beam you choose can shape the strength and safety of your project. Many people compare H-beams vs. I-beams because each has unique advantages depending on weight, load, and cost.

In this article, I’ll help you understand the differences, from their design and applications in construction to their use in engines.

You’ll see where each one works best, what mistakes to avoid, and how to choose the right option for your needs.

By the end, you’ll know which beam fits your project and why the decision matters. Which one do you think your build will need?

Understanding I-Beam and H-Beam

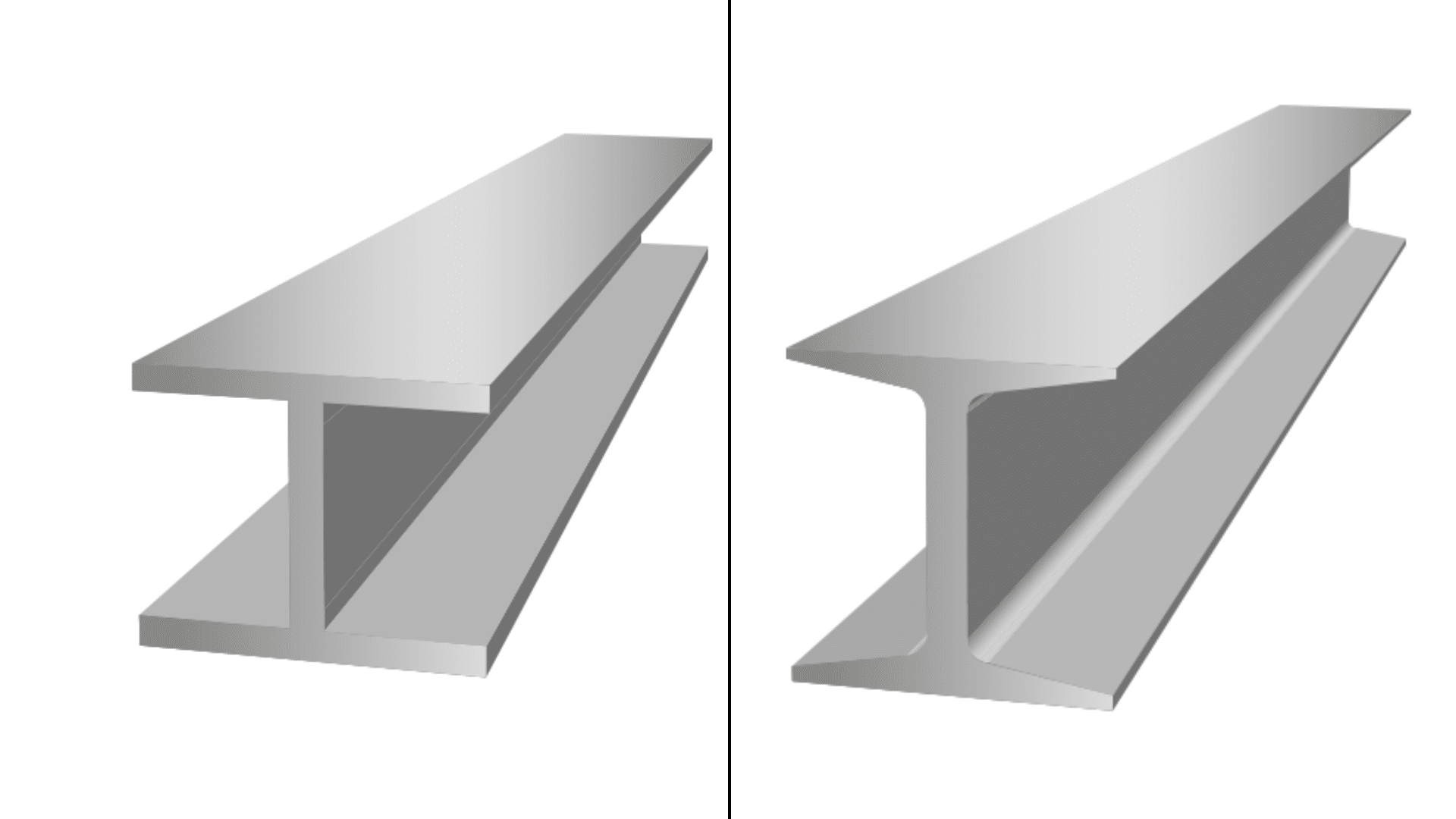

I-beams and H-beams are two of the most commonly used steel members in construction, each designed for different structural needs. While both provide strength and support, their shape and design determine how they perform under load.

I-beams have a thinner web and narrower flanges, making them lighter and suitable for smaller projects with moderate bending forces.

H-beams, on the other hand, feature wider flanges and a thicker web, giving them greater strength for handling heavy vertical loads and resisting twisting.

Because of these differences, engineers and builders often compare H-beams vs. I-beams when planning projects, ensuring they choose the right type based on span length, weight requirements, and structural safety.

Key Differences: I Beam vs. H Beam

The main differences between I-beams and H-beams involve their shape, weight, strength, and structural uses in projects.

Shape

The most visible difference in H beam vs. I beam comparison is their shape. The shape of an I-beam makes it lighter and efficient for handling bending loads in one direction.

This is why it works well in smaller structures with moderate span requirements. This design reduces material use, making them lighter.

The shape of an H-beam provides more surface area and stability, giving it the ability to resist twisting and support longer spans under heavy vertical loads.

This shape provides more surface area and strength, making it capable of carrying heavier loads and spanning longer distances.

Strength

Strength is where the H beam vs. I beam choice often matters most. I-beams handle bending loads in one direction, making them useful in applications like flooring or smaller structural frameworks.

H-beams are designed to withstand heavy vertical loads and twisting forces, giving them greater versatility for large-scale construction.

Their thicker web and wider flanges make them more stable under pressure, which is why engineers often choose them for demanding projects.

Weight

Weight is another key difference in the H beam vs. I beam discussion. I-beams are lighter because they use less steel, making them easier to transport and install. Their lighter weight also lowers costs for small to mid-size projects.

H-beams, however, are heavier due to their larger flanges and thicker web. This added material gives them superior load capacity but requires more effort and equipment during construction and installation.

Quick Comparison Table

| Feature | I-Beam | H-Beam |

|---|---|---|

| Shape | Narrower flanges, lighter design; best for bending loads in one direction | Wider flanges, thicker web; resists twisting and handles heavy vertical loads |

| Strength | Good for moderate spans and flooring; works under bending loads | Handles heavy loads, twisting forces, and long spans; more stable |

| Weight | Lighter, uses less steel; easier to move and install | Heavier due to more material; stronger but harder to handle |

This table gives you a clear snapshot of how I-beams and H-beams differ in shape, strength, and weight, so you can quickly decide which one makes sense for your project.

Applications in Construction: H beam vs. I beam Rods

Both beams serve vital roles in construction, but their applications differ depending on project size, load demands, and long-term goals. Here are some of the most common applications:

Where I-Beams are Used

I-beams are widely used in residential and light commercial projects because of their lighter weight and cost-effectiveness. They work well as floor joists, roof beams, and short-span supports where loads are moderate.

Their thinner web makes them easier to cut, transport, and install, saving time during construction. Builders often compare H-beams vs. I-beams to decide when lighter framing is appropriate without compromising structural safety.

Where H-Beams are Used

H-beams are chosen for large-scale projects that demand heavy load-bearing and resistance to twisting. Their wider flanges and thicker web make them ideal for high-rise buildings, warehouses, and bridges where stability is critical.

These beams provide the strength to support long spans and significant vertical loads. In the H-beam vs. I-beam comparison, H-beams clearly dominate in industrial and infrastructure applications due to their superior performance.

Choosing the Right Beam for Your Project

Selecting the right beam depends on your project’s structural needs, cost limits, and installation requirements.

I-beams are best suited for light to medium loads in smaller buildings, while H-beams are designed to handle heavy stresses in larger structures.

When deciding between H-beams and I-beams, consider the span length, budget, and labor requirements.

A simple rule: use I-beams for residential framing, and H-beams for major commercial or industrial projects.

Cost Comparison and Buying Guide

Cost plays a significant role in choosing between H-beams and I-beams, encompassing material pricing, installation effort, and sourcing decisions.

| Aspect | I-Beam | H-Beam |

|---|---|---|

| Price Differences Explained | Typically cheaper, uses less material, and is cost-effective in smaller projects. | More expensive due to the addition of steel and a thicker web design. |

| Installation and Labor Factors | Easier to transport and install; requires less heavy equipment. | Heavier, needs cranes, larger crews, and more time. |

| Buying Guide & Sourcing Tips | Check local suppliers, confirm adherence to AISC or Eurocode standards, and match the beam size to the project load. | Select trusted suppliers, verify their certifications, and factor in long-term maintenance costs. |

Making the right choice between H-beams and I-beams requires weighing the costs, labor, and sourcing quality to match your project’s needs.

H Beam and I Beam Rods in Engines

In engines, builders compare H-beam vs. I-beam rods to decide between lightweight efficiency and heavy-duty strength for performance applications.

What are Connecting Rods?

Connecting rods link the piston to the crankshaft, transferring combustion force into rotating motion. They are vital for engine performance, durability, and efficiency.

Different rod designs exist, but the debate often centers on H-beam vs. I-beam rods.

Understanding their shape, weight, and strength is key for engine builders choosing parts for everyday driving, racing setups, or high-performance turbocharged applications.

Differences in Engine Use

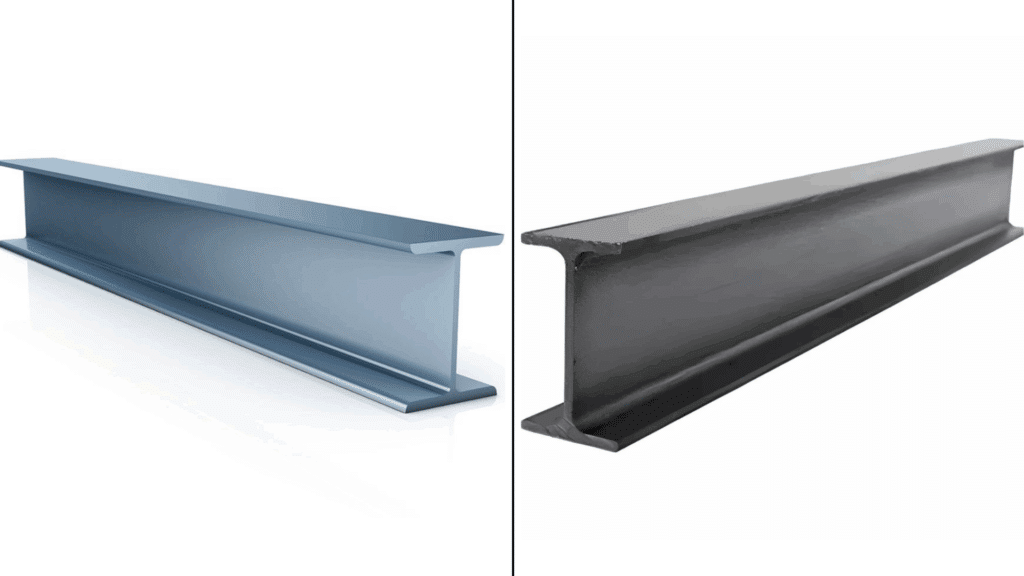

The comparison of H beam vs. I beam rods depends on the application. I-beam rods are lighter, reducing rotating mass and helping engines rev faster.

They’re often chosen for naturally aspirated builds or engines that prioritize speed over extreme stress.

H-beam rods, with thicker webs and wider flanges, handle higher loads and boost pressures, making them common in turbo or nitrous builds requiring extra durability.

Performance Factors to Consider

Engine builders weigh several factors when comparing H-beam vs. I-beam rods. I-beam rods perform well under inertial load, suiting high-rev engines.

H-beam rods excel under compressive load, managing extreme stress in forced-induction setups.

Daily drivers may favor I-beams for smoother operation, while racers rely on H-beams for reliability at high power levels. The final choice depends on performance goals, budget, and intended use.

Maintenance Tips for Beams

Proper upkeep extends lifespan and reduces long-term costs, especially where moisture, weather, or heavy loads can weaken steel structures. Here are some maintainance tips to consider:

- Apply protective coatings or paint to reduce corrosion.

- Inspect welds and joints regularly for cracks or stress damage.

- Ensure drainage systems prevent standing water around beams.

- Use galvanization for beams exposed to outdoor or marine environments.

- Schedule professional inspections for high-load or critical structures.

Conclusion

Now you understand the key differences in the H-beam and I-beam debate. You’ve seen how each performs, where they’re used, and what mistakes you should avoid.

I’ve shown you how to match the right beam to your project by looking at strength, cost, and long-term needs. Consider your goals before making a decision, as the right choice will save you time and money.

If you found this helpful, I suggest you keep reading other posts on the website to learn more about building materials and design!